Pellet have been defined as the feed formed by extruding individual ingredients or mixtures by compacting and forcing through die openings by an mechanical process”. Basically, the purpose of pelleting is to take a finely divided, sometimes dusty, unpalatable and difficult-to-handle feed material and, by using heat, moisture and pressure, form it into larger particles. These larger particles are easier to handle, more palatable and usually result in improved feeding results when compared to the unpelleted feed.

Pelleting prevents the segregation of ingredients in a mixing, handling or feeding process. By feeding a pelleted feed, the animal is more apt to receive a totally mixed ration than one that has separated through these processes.pelleted feed also produces a higher nutrient density and improves digestibility,thereby increasing animal performance while creating superior feed efficiency.

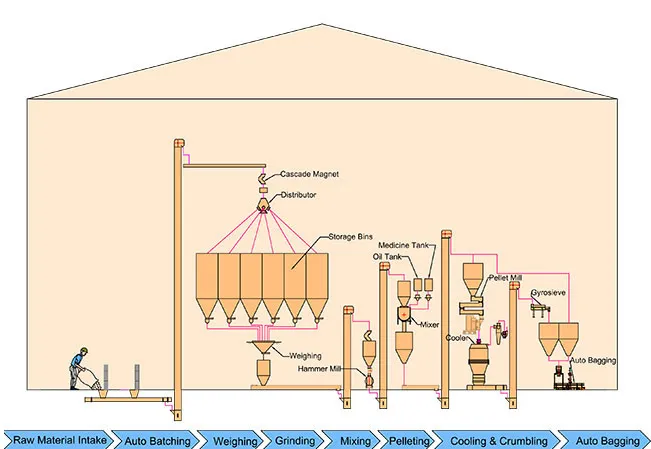

Pellet Feed Plant Process

Pellet Feed manufacturing refers to the process of producing animal feed from raw agricultural products. The manufacturing process usually start with the grinding process. Grinding of selected raw material is to produce particle sizes to be optimally and easily accepted by the animals. Depending on the formulation, feed could contain different components including carbohydrate, protein, vitamins, minerals and additives. After grinding Mixing process is done where uniformity in the complete feed is necessary and to satisfy nutritional requirements of the animal to achieve growth, production and good health as well and also meet regulatory guidelines of food administration. The feed can then be pelleted by proportionally homogenizing the specific compositions. Pelleting is achieved with help of Pellet Mill. A hygienic environment is important during the entire process of the feed production to ensure quality feed.

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Different Variants